SANDER NEVEJANS

Founder & CEO

Sander began his entrepreneurial journey in April 2021. He saw the untapped potential of byssus and set out to turn it into a viable product. With an electromechanical engineering and interior design background, Sander has +15 years of experience as a metal fabricator in Belgium and the UK. He has +9 years of experience as a retail, commercial, and hospitality interior designer for companies such as Ito Masaru Design Projects in Tokyo and B3 Designers, TurnerBates, and WATG/Wimberly Interiors in London.

MICHEL VANHOONACKER

Company Secretary

Michel studied economics in Belgium, and marketing in Bristol and has over 20 years of experience in industrial and office real estate, international business, and accounting in the UK. His day-to-day responsibilities include fundraising, cashflow follow-up, payroll, legal and property search. He has been involved in helping companies such as Meditech Health Automation Ltd and UZE Ltd set up in the UK and has access to a broad network of businesses and suppliers.

EMILIO CUEVAS

Advisor - Innovate UK Business Growth

Emilio holds an MSc in Entrepreneurship from UCL and a Law degree. While originally from Mexico, where he worked as a corporate lawyer in Banking & Finance and Capital Markets at Holland & Knight and was part of the founding team of a law firm. Emilio now supports startups on investment readiness, managing innovation and international expansion as Ecosystem Innovation & Growth Specialist at Innovate UK Business Growth through UCL Innovation & Enterprise.

In April 2021, an opportunity within the mussel industry came to our attention. a by-product called Mussel Beards, also known as byssus.

Our byssus material began its journey as nothing more than a by-product. Initially filled with broken shells, algae, sediment, and an unpleasant odour. this discarded by-product undergoes a transformative process through our exceptional eco-friendly clean & recycling technology redirecting it away from landfills, Incineration or biomass, and repurposing it into novel materials.

MISSIONs & PRINCIPLES

Replacing traditional Materials with Byssus Protein-Based Materials

We are dedicated to replacing petrochemical-based foams, fibres, and textiles with byssus protein inspired alternatives, ensuring they possess equivalent or superior technical properties to conventional materials.

Reduce CO2 emissions from critical industries to the greatest extent achievable.

We are committed to significantly reducing global CO2 emissions in the construction, furniture, textile, and mussel industries, marking a substantial stride towards a more sustainable future.

We provide a diversified income stream to the mussel industry.

Recognising the value in every aspect of mussel farming, we have introduced a unique solution by paying for the mussel waste. By doing so, we not only contribute to the sustainability of the industry but also create an additional source of revenue.

Sustainability is a fundamental part of our business model.

Sustainability is not just an add-on or afterthought, it is at the very core of our business model. As a company deeply committed to the health and preservation of our planet, we understand that our success is intertwined with the well-being of the environment.

SEASTEX LTD, Founded IN JUNE 2021, HAS pioneered the development of MUSSEL Beard products THROUGH its novel CLEANing and textile recycling TECHNOLOGIES, which are PAVING THE WAY FOR innovative, safe, and circular Materials.

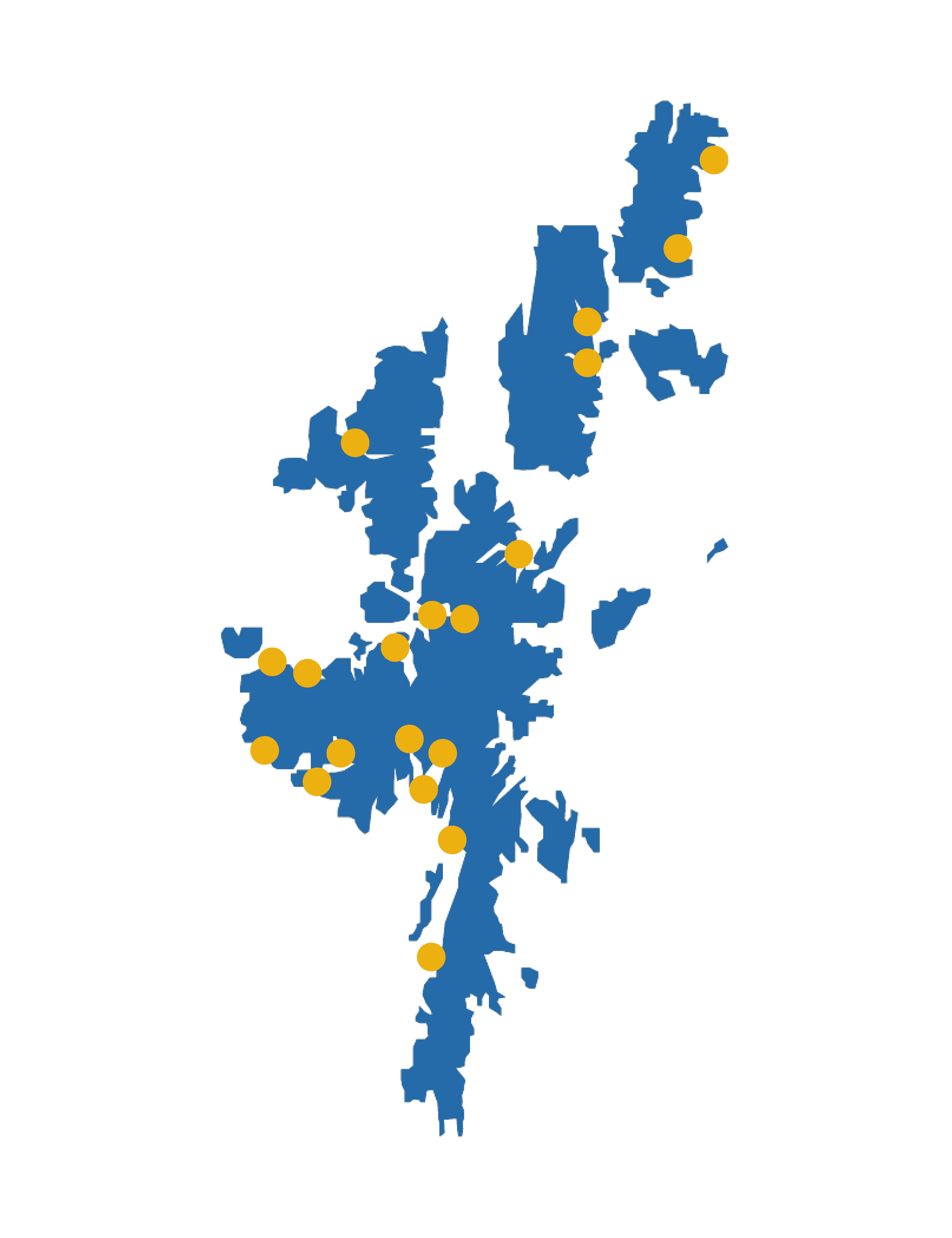

The first few years were dedicated to R&D, proof of concept testing, and developing byssus-specific technology alongside our MVP. All work remained confidential until the MVP was launched at the London Design Festival in September 2023. We now operate a Glasgow-based pilot facility that produces materials daily, year-round.

Value Propositions

Performance & safety

Mussel beard products are thinner and more efficient compared to traditional insulation materials. This means that when used as an acoustic or thermal insulator, less material is needed to achieve better results. We also offer fire protection through the natural fire-retardant properties of mussel beards. When compressed into panels, they effectively slow down the spread of fire.

Sustainability

Our innovative Byssus technology effectively reduces food waste from ending up in landfills, being incinerated, or used as biomass. Our products are manufactured use eco-friendly ingredients and requires less energy compared to conventional insulation materials. Moreover, as our material is 100% renewable, recyclable, and biodegradable, it has a minimal environmental impact. Our circular business model, involves paying for, collecting and reintegrating used mussel beard products into our production process.

Health and well-being

Our products reduce noise levels by absorbing sound waves. This fosters comfortable and less stressful environments, mitigating noise pollution and enhancing mental and physical well-being. Additionally, our mussel beards products emit no VOCs (Volatile Organic Compounds) which are harmful to humans because they can contribute to indoor air pollution.

Green Jobs

By pioneering the growth of this new industry and technology, Seastex generates green job opportunities in coastal communities and supports over 10 Sustainable Development Goals.

we collaborate with our partners to facilitate a smooth shift from petrochemicals to our natural alternatives with more opportunities on the horizon.

By continuously recycling natural byssus, we can further streamline and develop our prototype processing technology to efficiently and sustainably repurpose textile by-products from other industries, surpassing the effectiveness of current textile recycling solutions.

We are part of the Ellen MacArthur Foundation community and keep byssus in circulation, thereby eliminating its environmental footprint. Our materials are 100% renewable, recyclable and biodegradable.

In-house research has revealed promising results regarding the extensive applicability of byssus threads when utilised as a non-woven fibre. As part of our sustainability commitment, our byssus technology enables us to seamlessly incorporate mussel beards from old products into new ones. This process ensures byssus materials are continuously reused, extending their lifecycle indefinitely.